3D Custom Insoles

3D Custom Insoles from NC Foot Health

3D printing is the product of using computer aided design (CAD) to create a three-dimensional object through a layering method. More and more foot practitioners around the world are using 3D printing to create an orthotic insole for their patients.

There are many reasons to love 3D printing apart from them looking and feeling incredible. Every patient is unique, they’re built in their own way, walk in their own way, and require orthotic insoles that reflect that by ensuring that they are completely personalised to the movement and shape of your foot with greater accuracy seen than ever before.

NC Foot Health are very fortunate enough to have partnered with Foot Health Orthotics UK to become an official co-lab printing manufacturer, which means we have our very own in-clinic printer which enables us to have a much quicker turn around for our patients.

What is involved?

There are 4 steps standing between you and being able to say goodbye to that foot pain.

We do ask you before your appointment to please wear shorts or leggings (that you can roll up over the knee), we also require you to bring a selection of your footwear so we can assess the fit. Very important that with children under the age of 18, you must bring their school shoes.

1. Medical History

Firstly one of our qualified and registered practitioners will have an in-depth conversation about all of your concerns, they will have a thorough look through previous medical history, and a copy of current medication will be taken. In some cases, further circulatory and sensitivity tests may be carried out if the practitioner deems this appropriate

2. Biomechanical Assessment

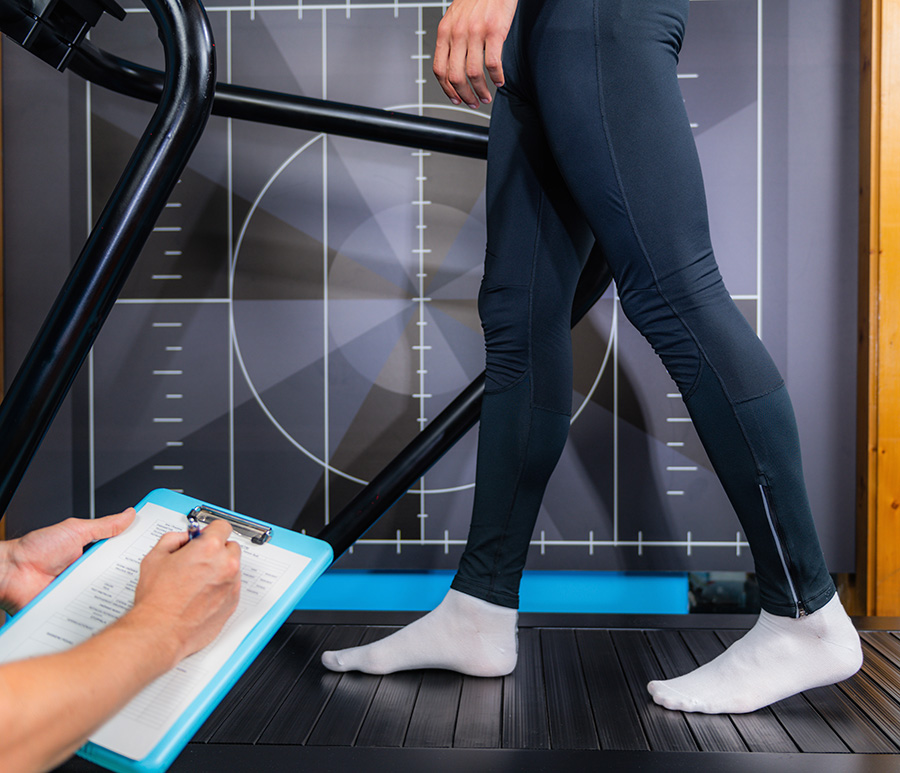

To begin our diagnosis, the practitioner will start with a postural analysis, whereby they will start at the foot and work all the way up the body looking for any static weight baring misalignment issues. Following on from this the practitioner will ask you to walk on our treadmill, this will be recorded so that they can give you an in-depth analysis of foot and ankle structure. A range of movement exercises will then be conducted to look and note any other abnormalities that may be part of your problem.

3. 3D Scan

The practitioner will then set up the 3D scanner and scan both of your feet. For this we will need to you lay down or kneel on our couch so that we can scan the whole foot.

4. Prescription Overview

This is the part that should be the most exciting, as we are only one step away from you embarking on a whole new journey. We will talk you through every step of what we will incorporate into the design process, when you are happy, we will send it to the design team at Foot Health Orthotics UK

Considerations

We always quote 3 weeks for our orthotics to be designed and printed, our admin team will contact you and book an appointment to have them fitted once they have been printed.

We offer three separate alterations to the prescribed orthotic should the practitioner deem it appropriate to achieve optimum results. This is included within the price of the insoles. It is very important that to achieve great results with the insoles, patients must follow the step-by-step adjustment plan that the practitioner will issue you with on the day of the orthotic fitting. It is also paramount that the correct footwear is also being worn, failure to do this may result in the orthotics not working to their true potential thus potentially causing you more discomfort.